ReHub

ReHub Glove: sensor hub glove

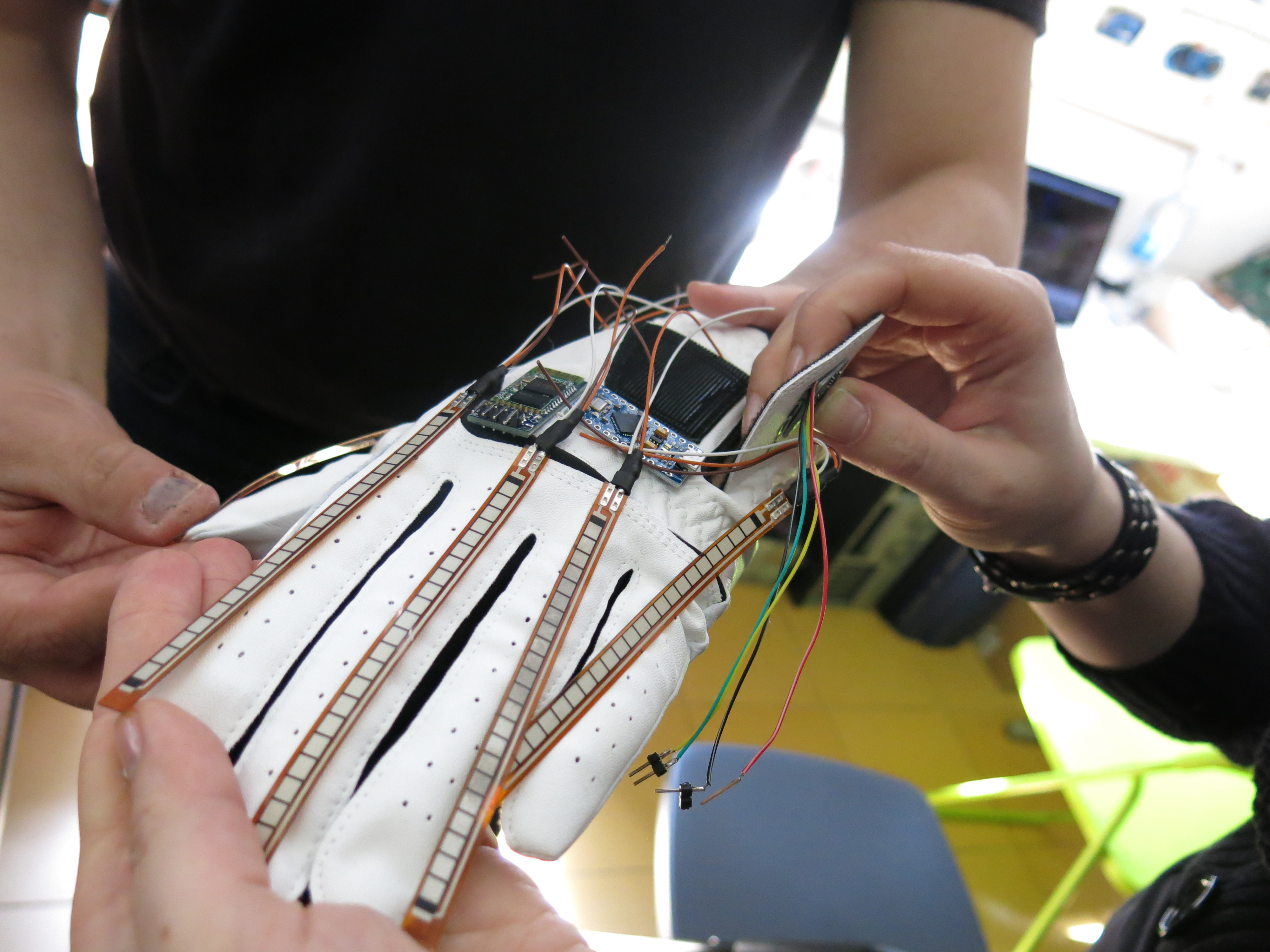

Hacking gloves

Research and experimentation, true nature of these first six months of work on reHub, affected the glove’s design.

Not having either funds nor time to develop an “ad hoc” model, we opted for an analog-hacker solution: we bought two right and left gloves from a famous retailer. The selection of these gloves was not random: we favored light colors, a fitted look with leather, leatherette and stretch fabric parts.

We wanted to realize a prototype used by a wide range of people (size L) and to be able to remove the electronic part to make changes or simply wash the glove.

The electronic components we used determined our glove design. Our prototipe allows all sensors to be protected and keeps them sufficiently isolated from the patient’s hand, without compromising the reliability of the data collected during different stages of physiotherapy treatment.

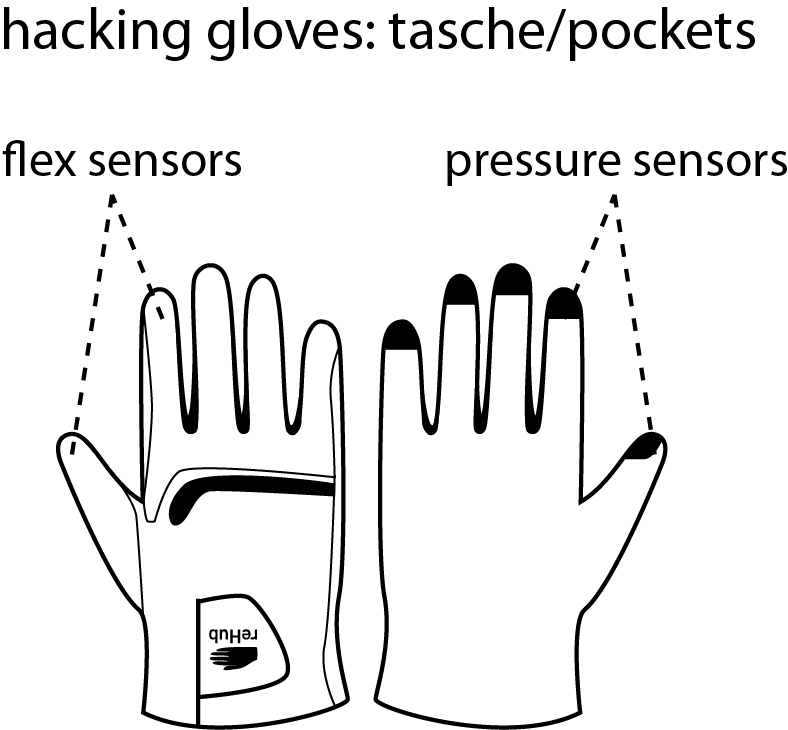

Flex sensors run along fingers while pressure sensors stops at glove’s fingertips allowing us to acquire useful values.

Hand made seams, such as slipstitch and backstitch, are featured on most of sensor’s pockets. The only seams made with an industrial sewing machine, with durable yarn in a light color slightly contrasting, are those present along the length of the fingers.

Electronics influences design influencing electornics

As we could experience working in the field of wearables there are many variables to take into account. Future scenarios of our experiments include a journey into the world of yarns and silicones.

© 2016-2019 - reHub. All Rights Reserved.