ReHub

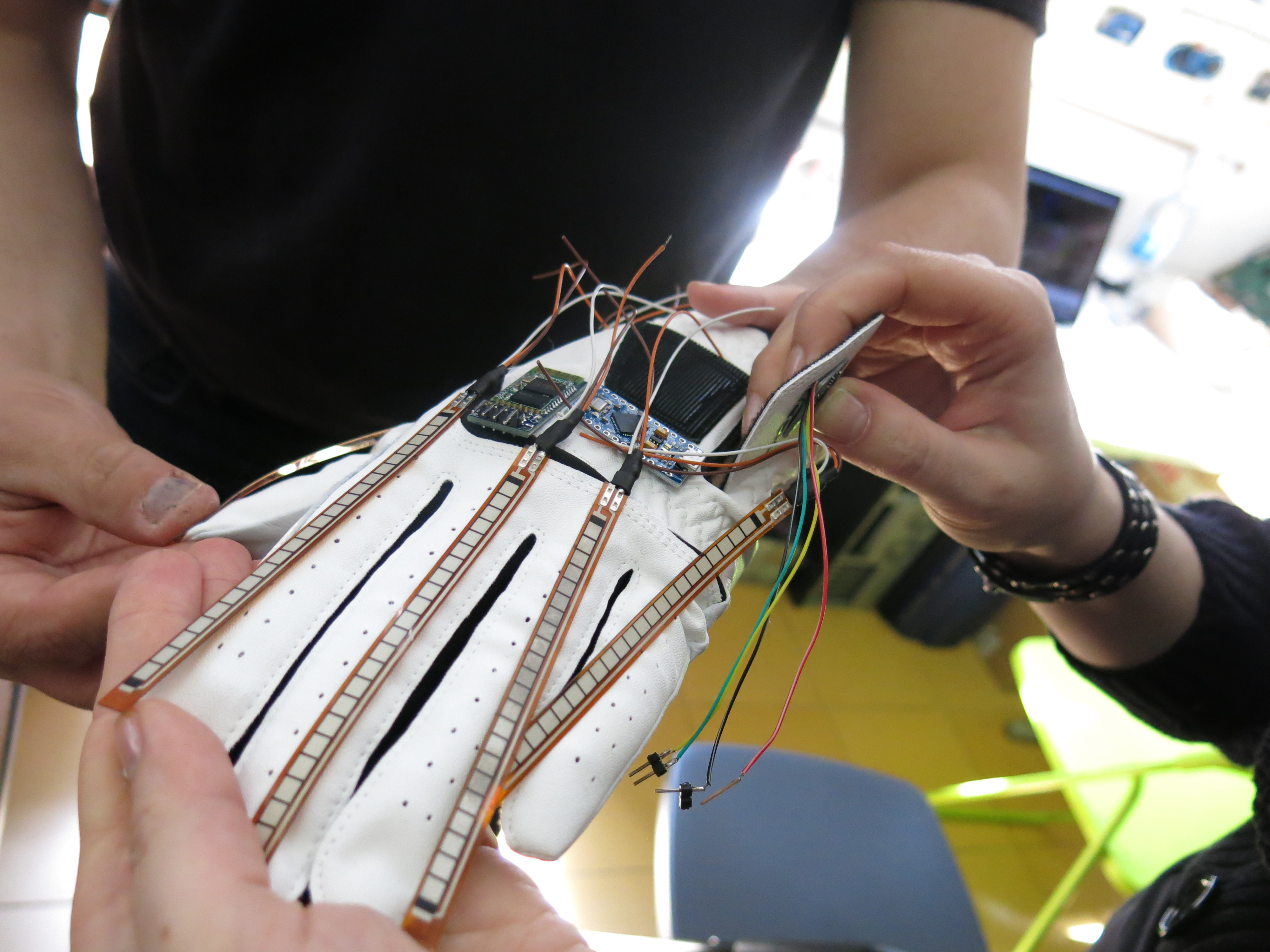

ReHub Glove: sensor hub glove

Electronics

Electronics selection and design has gone hand in hand in the implementation of wearable support: reHub glove.

Research and development of electronic components engages us every day: our goal is to optimize the performance of the parts and reduce production costs in order to make reHub technology accessible to as many users as possible.

Electronic parts were involved during the first phases of the project’s feasibility study: we verified the possibility to accurately detect how fingers moves using commercial flex sensors appropriately integrated with the glove. Our first prototype had an Arduino microcontroller connected to five flex sensors to verify both detectable characteristics and sampling rate, processing of the data to the log and render graphics softwares.

Sensors evaluation is the main part of the feasibility study for the construction of reHub glove.

ReHub main sensors are:

_ flex sensors

_ pressure sensors

_ 6DOF position sensors (3DOF Accelerometer and Gyroscope)

Flex sensors

Flex sensors allow reHub glove to acquire informations related to the corner of each flexed finger.

In reHub’s first prototype we used a bending sensor for each finger: five sensors of the same length, for each glove, allowed us to test the feasibility of the project and realize the ineffectiveness of some sensors.

For example those linked to the thumb and the pinkie were too long.

The use of a longer sensor compared to the related finger caused a limited range of detected values.

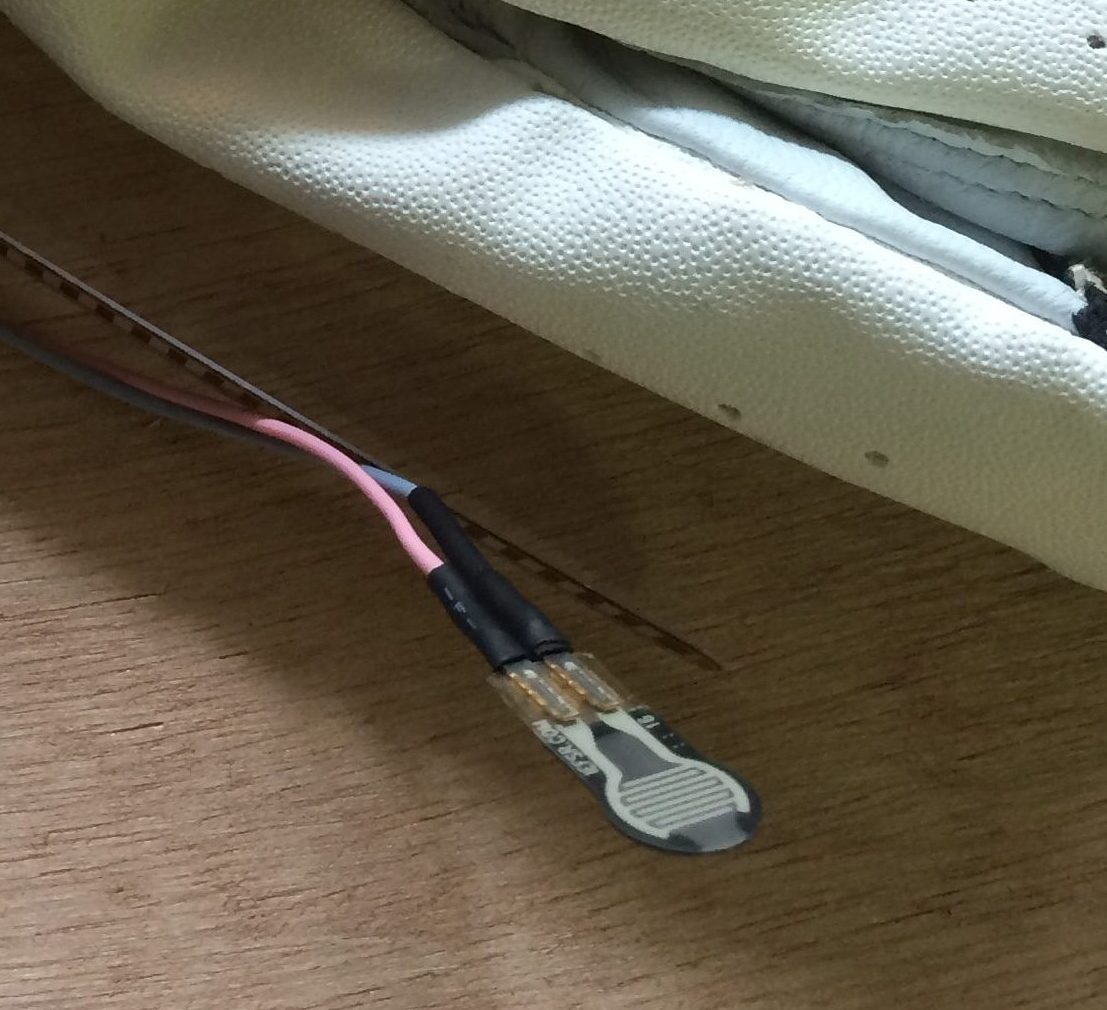

Pressure sensors

In our first prototype we avoided the introduction of this type of sensor leaving to a second prototype testing, study and analysis of data from five additional sensors placed on fingertips.

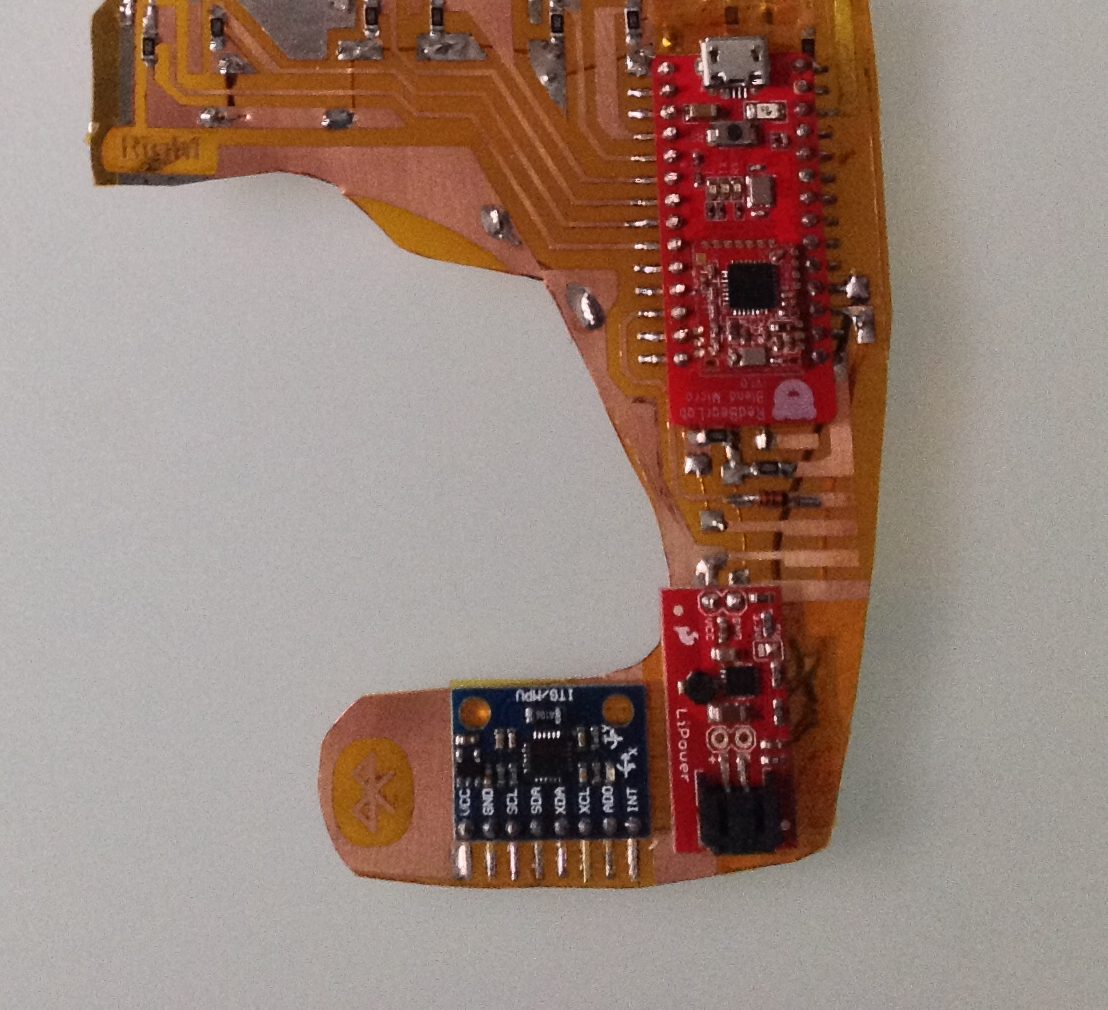

6DOF position sensors

Hand detection in space has been one of the main aspects involved in the feasibility study. Since the first feedback we focused on the possibility to detect the hand position using accelerometers and gyroscopes.

© 2016-2019 - reHub. All Rights Reserved.